Success story

As a designer of materials and innovative solutions, Arkema shapes materials and creates new uses that accelerate customer performance in lightweight and design materials, biosourced materials, new energies, water management, solutions for electronics, and the performance and home insulation.

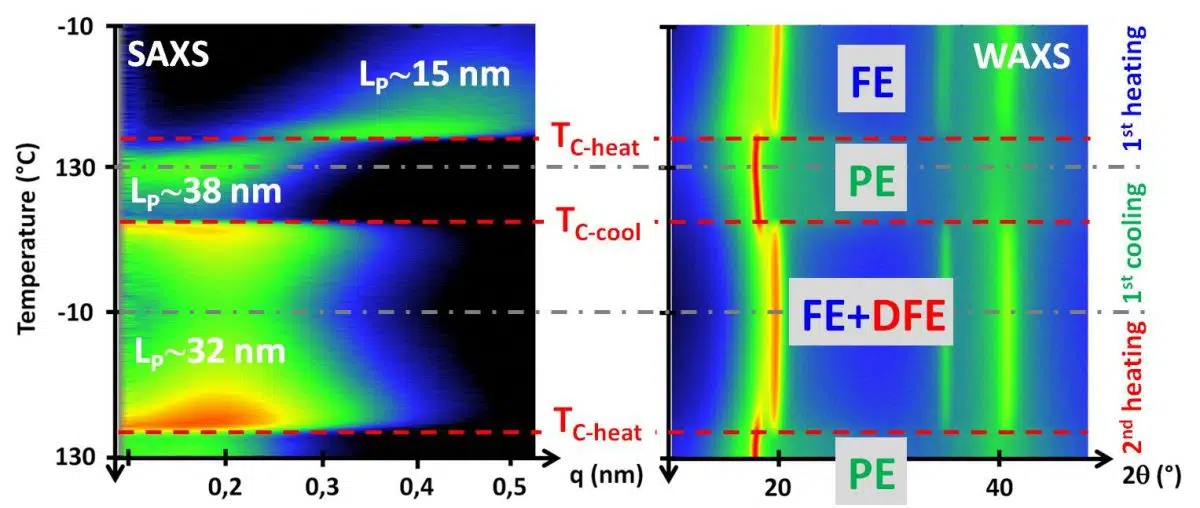

For the development of new polymers, Arkema used to characterize materials with two dedicated X-ray instruments, one for running Small Angle X-ray scattering (SAXS) experiments, and one for Wide Angle X-ray Scattering (WAXS) experiments.

As new high-performance materials need to have improved macroscopic properties such as resistance at high temperature, it became essential for Arkema to have a perfect knowledge of the structure and morphology of their samples at each temperature of use, and to understand the key role of annealing. In situ analysis during a thermal cycle became central.

With the existing equipments at Arkema, the very long exposure time and the non-simultaneous SAXS/WAXS measures made operando studies impossible. Arkema did some experiments at synchrotrons as an alternative but the cost and availability of synchrotrons were not compatible with Arkema’s daily analysis needs.

Thanks to a co-development project between Arkema and Xenocs, the Nano-inXider was designed and built to answer Arkema’s and other industries’ needs. With the Nano-inxider, in situ analysis with control of sample temperature is possible in SAXS and WAXS simultaneously. This easy to use equipment can be operated by a technician.

With short exposure time and an intuitive and powerful analysis software, Arkema has considerably improved the throughput of their X-ray analysis on polymers. With fast and accurate information on the nanostructure of the sample, Arkema can now focus on science.

Future specific developments on some other dynamic sample environments are under discussion between Arkema and Xenocs to support Arkema’s research on polymers further.