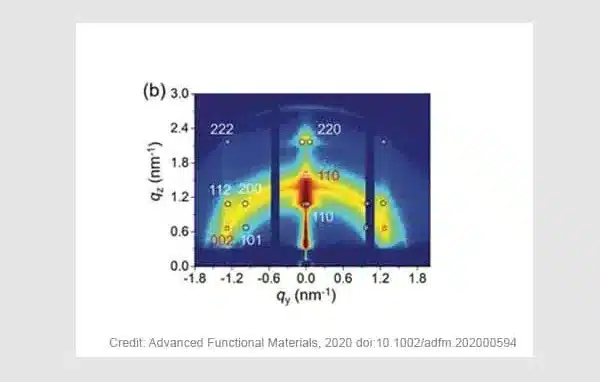

Mass specific surface area determined by SAXS

Download the application note

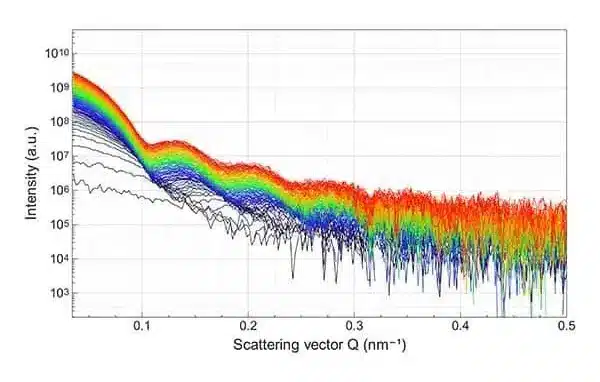

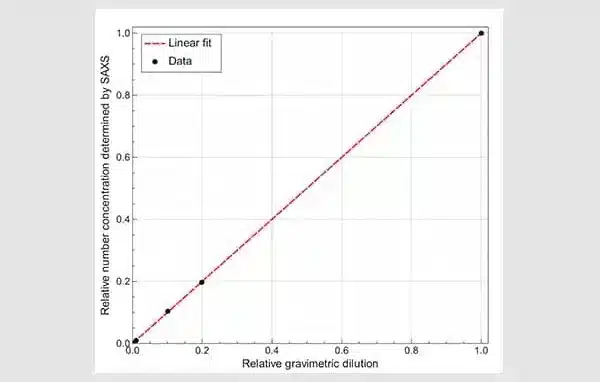

DownloadSAXS has been used for a rapid and reliable determination of the specific surface area of a SiO2 powder sample

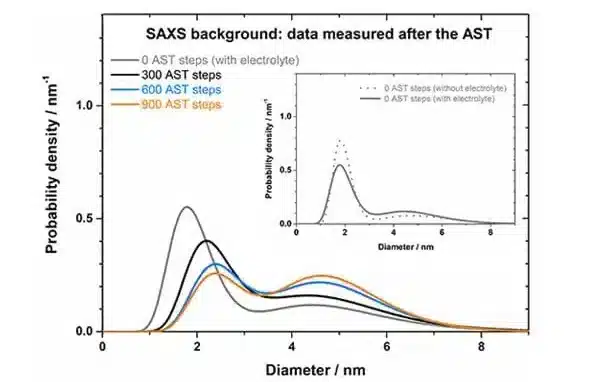

The specific surface area is a particularly important physical property of solids. It is defined as the total surface area of a material per unit of mass and depends on the dimensions of the particles, but also the material’s structure and porosity. The most used methodology for determining the specific surface area is based on gas adsorption analysis (usually employing nitrogen, argon or krypton) using the Brunauer-Emmett-Teller (BET) method.1,2 This method has, however, certain limitations such as the high amount of time required for sample preparation and measurement (sample conditioning (degassing) takes several hours in addition to the several hours necessary for the actual measurement) or the necessity to evacuate water or solvent from the sample which can lead to modifications of the microstructure, for example in samples that are in gel state.3

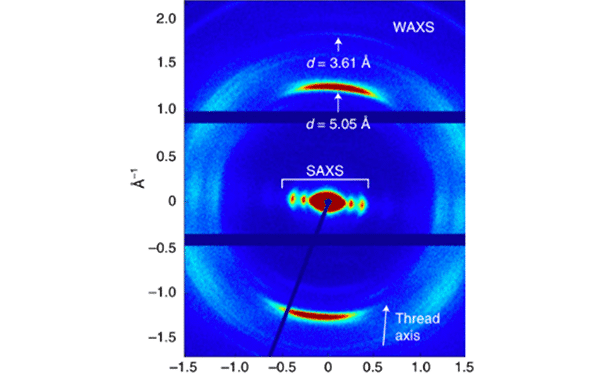

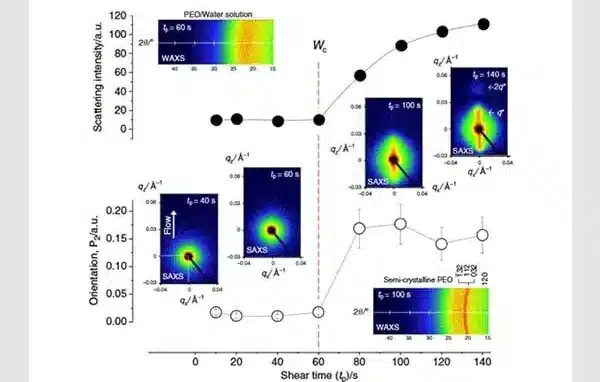

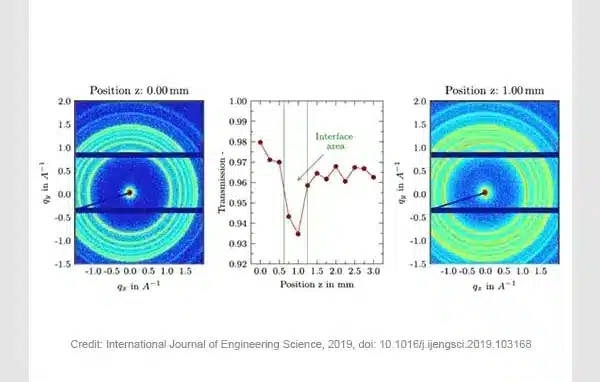

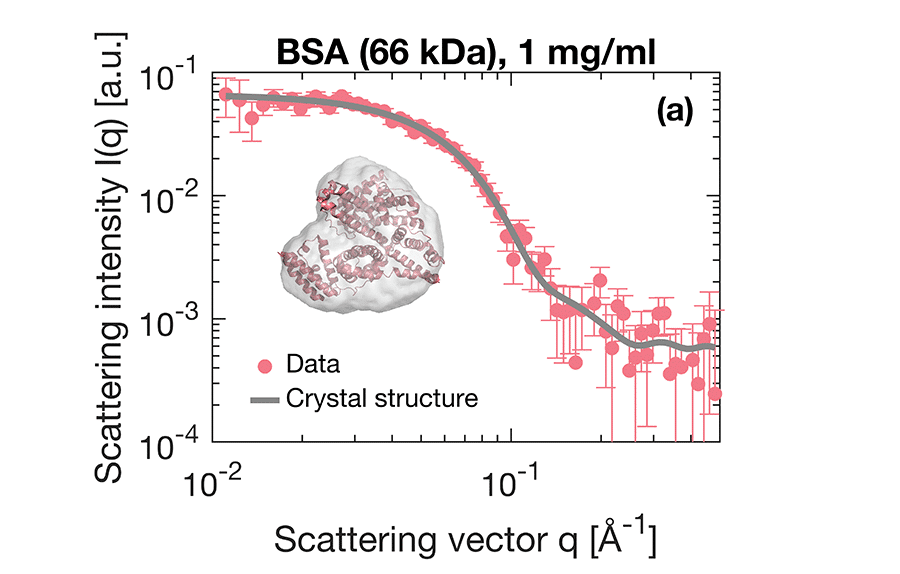

Small angle X-ray scattering (SAXS) offers the possibility to determine the specific surface area of nanoparticulate systems, but also of nanoporous materials with open or closed pores or inclusions if there is a sufficient electron density contrast between the matrix and the filling. Moreover, sample preparation requirements are minimal, and the measuring times are generally short in contrast with the BET method.4

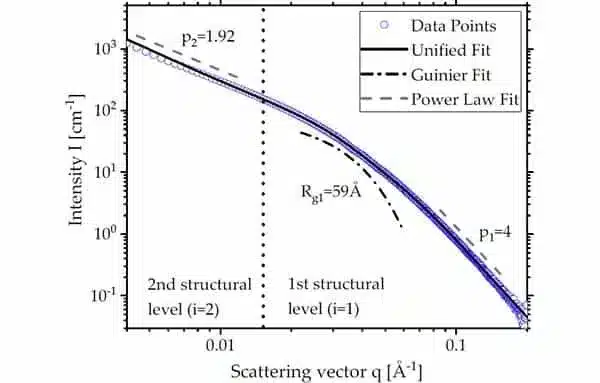

In determining the specific surface area from SAXS data, two evaluation methods, both based on the Porod law and associated fit, can be used:

- the invariant (K/Q) method

- the absolute-scale method.

In this Application Note, we use the XSACT software package to process the SAXS data and determine the specific surface area of two SiO2 powder samples of different thicknesses. Both the invariant and the absolute-scale methods are employed, and the results are compared with the obtained from BET measurements and analysis.4

References:

1 Brunauer, S., Emmett, P. H., & Teller, E. (1938). Adsorption of gases in multimolecular layers. Journal of the American chemical society, 60(2), 309-319.

2 International Organization for Standardization. (2010). Determination of the specific surface area of solids by gas adsorption — BET method (ISO 9277:2010).

3 Ghernaouti, F., Perrin, A., Causse, J., Chandre, F., Cornu, D., & Cambedouzou, J. (2022). Small angle x-ray scattering to investigate the specific surface of hydrated alginate microbeads. Food Hydrocolloids, 127, 107498.

4 International Organization for Standardization. (2022). Determination of the specific surface area of porous and particulate systems by small-angle X-ray scattering (SAXS) (ISO 20804:2022).