The MATEIS laboratory at INSA Lyon, a hub for materials science research, has found a powerful ally in the Xeuss 3.0 SAXS/WAXS instrument. The purchase of this instrument was made possible through financial support from the Auvergne-Rhône-Alpes region (Funding: CPER PROPRE). To promote the use of X-ray scattering in materials science, the SAXS/WAXS Xeuss 3.0 instrument has been integrated into a platform managed by the MATEIS laboratory.

The decision to adopt this advanced instrument was driven by the need for simultaneous SAXS/WAXS measurements. Moreover, it also aimed to improve ease of use in a shared lab environment. In particular, Prof. Angelo Pommella shares how the Xeuss 3.0 has revolutionized their approach to polymer characterization and enhanced their research capabilities.

Simultaneous SAXS/WAXS: A Key Feature for Comprehensive Material Characterization

A standout feature of the Xeuss 3.0 for the team at INSA Lyon is the motorized SWAXS module, which enables simultaneous SAXS and WAXS measurements. The dual detector setup combines the main Q-Xoom detector for SAXS and a 3-axis motorized WAXS detector. Thus, this configuration allows for simultaneous collection of both in-plane and out-of-plane scattering data. According to Prof. Angelo Pommella, “We particularly appreciated the ability to perform simultaneous SAXS/WAXS measurements coupled with mechanical tests.”

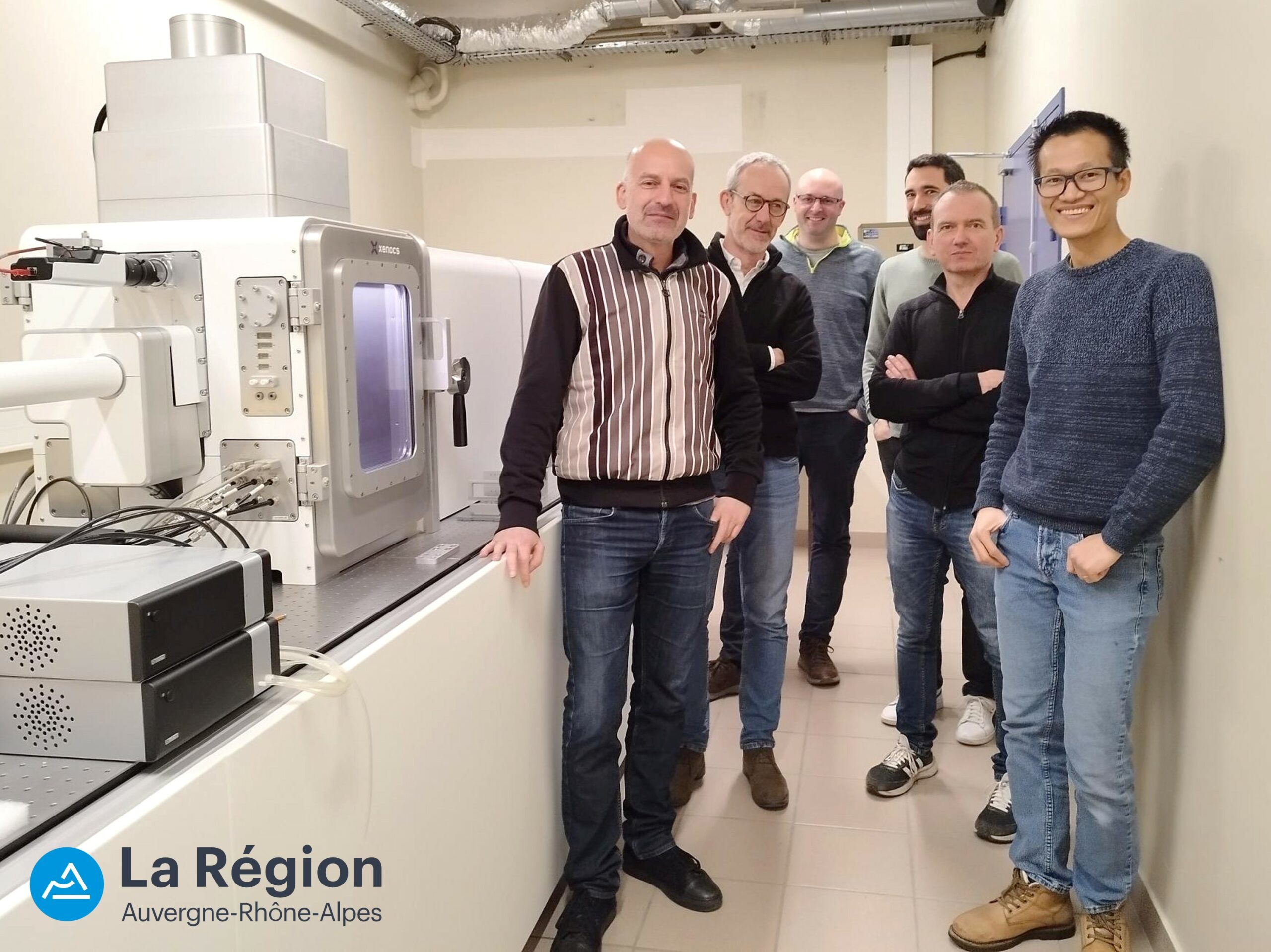

From left to right: Dr. Jean-Marc Chenal, Dr. Paul Sotta, Dr. Damien Montarnal, Dr. Guillaume Sudre, Dr. Bruno Gardiola, Dr. Tra Nguyen

A Wide Range of Polymer Studies: Synchrotron-Level Performance in the Lab

The research team at INSA Lyon has primarily focused on a wide range of polymer samples, including semi-crystalline materials and elastomers. In addition, their work extends to polymer gels, aerogels and liquid solutions containing nanoparticles or samples of polymer coils. Leveraging the power of the Xeuss SAXS/WAXS instrument, the team has delved into the characterization of polymer crystallinity in samples under controlled deformation. By coupling WAXS with a tensile stage, they can gain valuable insights into the stress-induced behavior of these materials.

Several advanced features of the Xeuss 3.0—such as the noise-free detector, the beamstop-free operation, and the stable X-ray beam—have significantly enhanced data quality. Prof. Pommella described this improvement as “comparable to synchrotron-level measurements, albeit on longer timescales. Moreover, this high-quality data, along with the ability to perform measurements more frequently, has deepened their understanding of the polymers. It has allowed for a better understanding of their complex structures and behaviors.

Effortless Operation and Automation with the Xeuss

Furthermore, one of the defining advantages of the Xeuss 3.0 is its user-friendly design. The instrument’s intuitive software, coupled with fully automated alignment, allows the research team to quickly set up experiments and focus on the scientific questions at hand, rather than on technical aspects of the setup. “The fully automatized aligning of the X-ray setup allows you to completely focus on the scientific aspect of the measurement without spending too much time on the technical side of the setup.”, explains Prof. Pommella.

This ease of use has been a key benefit for the laboratory, where 15 different users from various research groups within INSA Lyon and the University of Lyon, are now effectively utilizing the Xeuss 3.0, without needing extensive technical expertise.

Expert Support, Every Step of the Way

Finally, the team at INSA Lyon has been particularly pleased with the level of customer support provided by Xenocs. From the initial installation to ongoing assistance, “The customer support has been excellent,” says Prof. Pommella, “They allowed us to start using the Xeuss 3.0 very quickly, and we continue to receive invaluable assistance whenever we need it.”

In addition to responsive support, the training provided by Xenocs was praised for its clarity and comprehensiveness. The research team appreciated how Xenocs’ experts answered all their questions and continued to assist them after the initial training. This ongoing assistance helped them fully maximize the potential of their Xeuss 3.0.

About MATEIS Laboratory

The MATEIS laboratory is located at the intersection of chemistry, physics, and mechanics. It focuses on studying three main classes of materials—metals, ceramics, and polymers—and their composites, while integrating their characteristics in volume, surface, and interfaces. The laboratory’s primary research axes include:

- The development of advanced material processes to create new microstructures and architectures that meet evolving requirements and increasingly high multifunctional constraints.

- The characterization and evolution of microstructures across various length scales.

- Investigating the relationships between microstructure and macroscopic behavior at different scales, from nanometers to millimeters, using a variety of characterization techniques such as mechanical, physical, and electrochemical methods.

- Examining the evolution of materials during use and their interaction with the environment, as part of a systemic approach.

About INSA Lyon

INSA Lyon is a leading engineering school with strong humanist values that have formed the basis of its business model for more than 60 years. INSA Lyon boasts 22 research laboratories, more than 700 researchers and teacher-researchers, about 600 PhD students, and over 1,000 industrial contracts with the socio-economic world. Constantly working with companies and the industrial sector, our centers are specialized in several areas. It is a unique opportunity for our students to obtain a high quality research experience in one of our research centers. This represents a scientific and technological capital that accounts for much of the international prestige of the school.

Contact: Prof. Angelo Pommella, [email protected]