Dealloyed hierarchical nanoporous metals have emerged as a novel category of functional materials exhibiting large specific surface areas at the lower hierarchical structural level and open nanopores with tunable sizes at the upper level. Their unique structural properties, such as high electrical conductivity which renders them ideal for use in electronic and energy storage devices, or their innate high corrosion resistance and mechanical rigidity, which make them good candidates for applications in harsh environments, positioned them as promising materials for a wide range of applications across multiple industries.

Recently, a group of researchers from Helmholtz-Zentrum Hereon and Hamburg University of Technology [1] demonstrated the possibility of independently tunning the microstructure of the two hierarchical levels through variations of the dealloying conditions, such as the applied potential and the annealing treatment. A combination of laboratory small and ultra-small angle X-ray scattering (SAXS and USAXS) measurements proved to be an excellent probing method to investigate representative and statistically meaningful ensembles of microstructural features on the two distinct lengthscales simultaneously.

Synthesis, preparation and measurement methods

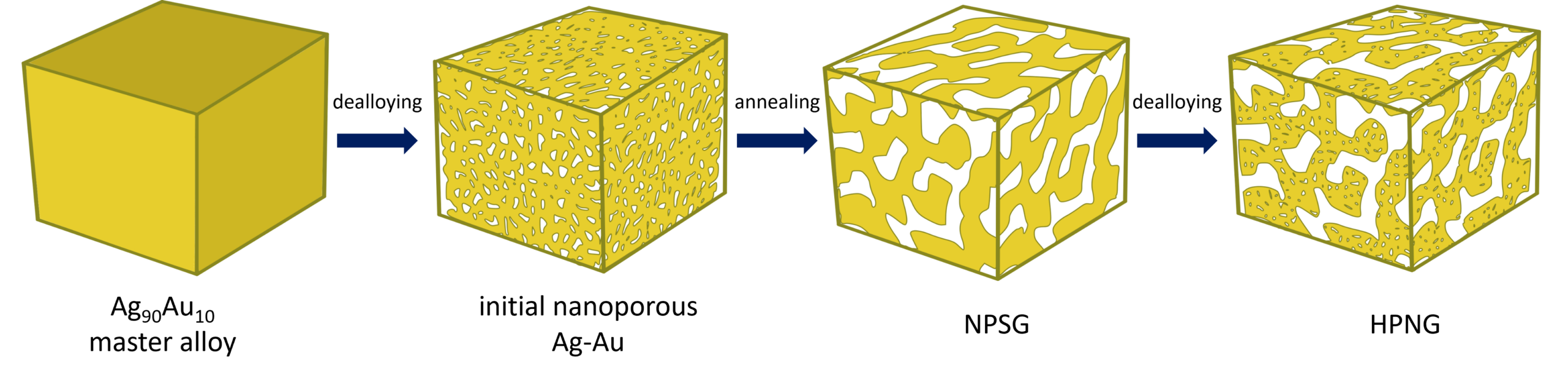

In the aforementioned study, a 2-step dealloying synthesis method [2] is employed to demonstrate the tunability of the microstructure independently for the two hierarchical levels of nanoporous gold based on the master alloy Ag90Au10. Firstly, a coarsened nanoporous silver-gold (NPSG) material is obtained through a dealloying step followed by annealing. A subsequent second dealloying process is then used to remove the residual Ag generating thus hierarchical nanoporous gold (HNPG) samples. Figure 1 shows a graphical representation of this process.

Fig. 1 Schematic illustration of the 3-steps synthesis process [2] of hierarchical nanoporous gold: first dealloying of a Ag-rich precursor alloy results in a nanoporous network with high amount of residual Ag; coarsening of the ligament structure by thermal annealing produced a nanoporous silver-gold (NPSG) material; finally, a second dealloying step removed the residual silver and forms the lower level nanoporous microstructure thus obtaining a hierarchical nanoporous gold (HNPG) sample. Image inspired by refs. [3,4].

By studying a series of samples produced in different conditions and prepared using a plasma focused ion beam cutting instrument, the influence of the synthesis parameters on the final structure were determined. For this, the ligament spacings of both upper and lower hierarchical levels are quantitatively assessed through a combination of SAXS and USAXS measurements and scanning electron microscopy (SEM). This allows an evaluation of the capabilities of the two techniques and a comparison of the results.

Traditionally, SEM (scanning electron microscopy) and tomographic 3D characterizations have been the primary tools for studying material structures. However, these techniques often face challenges when attempting to simultaneously address multiple size scales within the same sample in a statistically meaningful way.

In contrast, continuous SAXS and USAXS performed on a laboratory instrument allows for the measurement of scattering intensities over a wide range of scattering vectors (q) with a high resolution and representative of statistically meaningful ensembles. This enables the simultaneous characterization of the two distinct length scales within the hierarchical metal. Moreover, the thorough analysis of both SAXS/USAXS and SEM data enabled the determination of a conversion factor for mean ligament diameters between the two metrics.

The study revealed that the ligament spacing of the upper hierarchy level (L̃U) can be tuned by varying the annealing temperature (TA) and that the lower-level ligament spacing (L̃L) can be tuned by modifying the dealloying potential (ED) during the second dealloying step.

Structural evolution of hierarchical nanoporous gold as revealed by SAXS and USAXS analysis

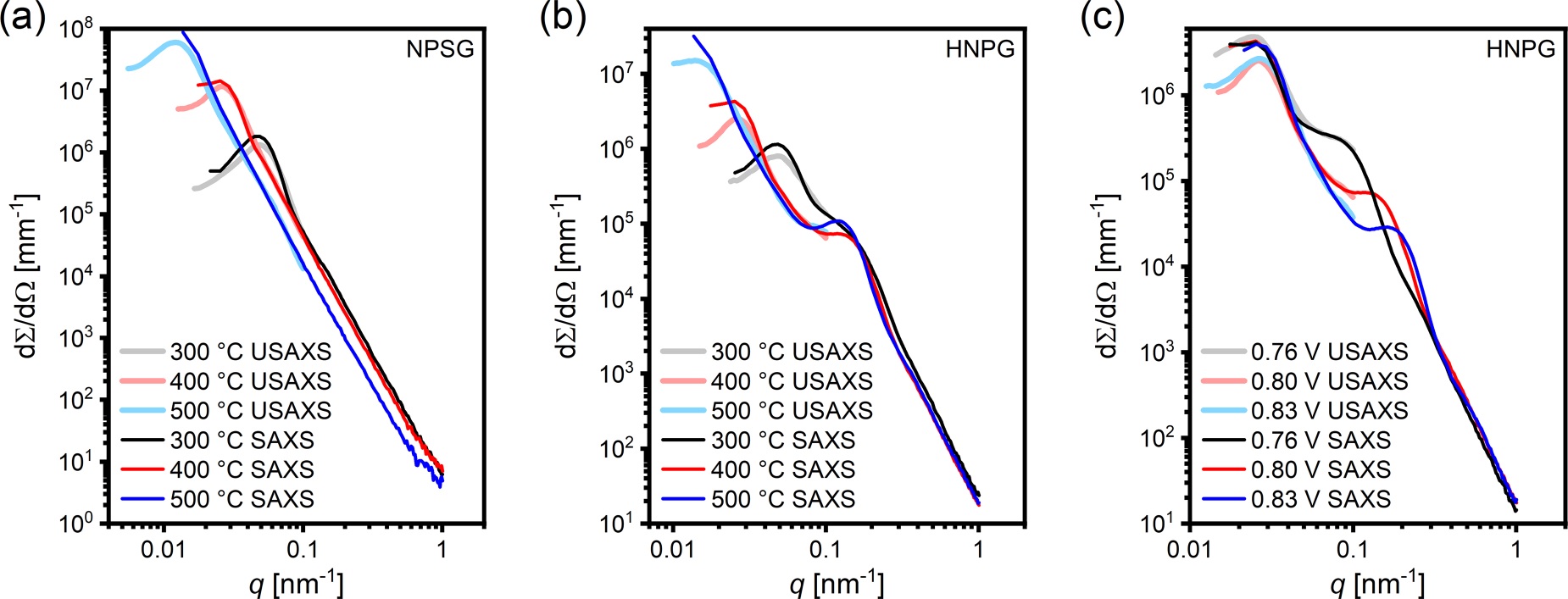

Both small and ultra-small angle X-ray scattering measurements reveal the well-known interference peak suggesting a high degree of structural definition with one or two dominant ligament spacings (in the case of scattering graphs exhibiting two interference peaks). Figure 2 showcases SAXS and USAXS graphs of samples in various conditions: NSPG samples after 1st dealloying and annealing at different TA (Fig. 2 (a)), analogous scattering graphs of HNPG samples that experienced a second dealloying treatment at ED = 0.80 V (Fig. 2 (b)) and HNPG samples synthesized with the same TA = 400 oC and different ED (Fig. 2 (c)).

Fig. 2 Small and ultra-small angle X-ray scattering graphs of samples produced with different synthesis parameters: (a) Nanoporous silver-gold (NPSG) samples prepared with different TA; (b) hierarchical nanoporous gold (HNPG) samples prepared with different TA but identical ED = 0.80 V; (c) HNPG samples prepared with same TA = 400 ◦C but different ED. Credit: Phys. Rev. Mater., 2023 DOI: 10.1103/PhysRevMaterials.7.116001.

For NSPG samples the effect of increasing TA is to shift the interference peak to lower q values indicating the formation of larger structures (Fig. 2 (a)). It is important to note that while SAXS measurements provide a sufficient q-range and resolution for samples prepared at low TA, the larger pore structure obtained using a high annealing temperature (TA = 400 and 500 oC) could only be resolved by additionally employing USAXS measurements. This combination of methods extended the probed q-range from the lower limit of SAXS q = 0.015 nm-1 down to 0.003 nm-1. Moreover, the excellent agreement between the ligament spacing values obtained through the two methods (USAXS values vary between 97% and 102% of the SAXS ones) validates the combination of SAXS and USAXS for characterizing hierarchical porous structures that exhibit significant variations in length scales across individual hierarchy levels.

The upper-level structure of NPSG and behavior as a function of annealing temperature are preserved in HNPG samples which exhibit an additional interference peak at higher q values attributed to the lower hierarchical level produced by the second dealloying step (Fig. 2 (b)). It is evident from the graphs presented in Figures 2 (b,c) that the size of the lower-level microstructure can be controlled by modifying the dealloying potential during the second dealloying step: a higher ED is responsible for generating a smaller structure.

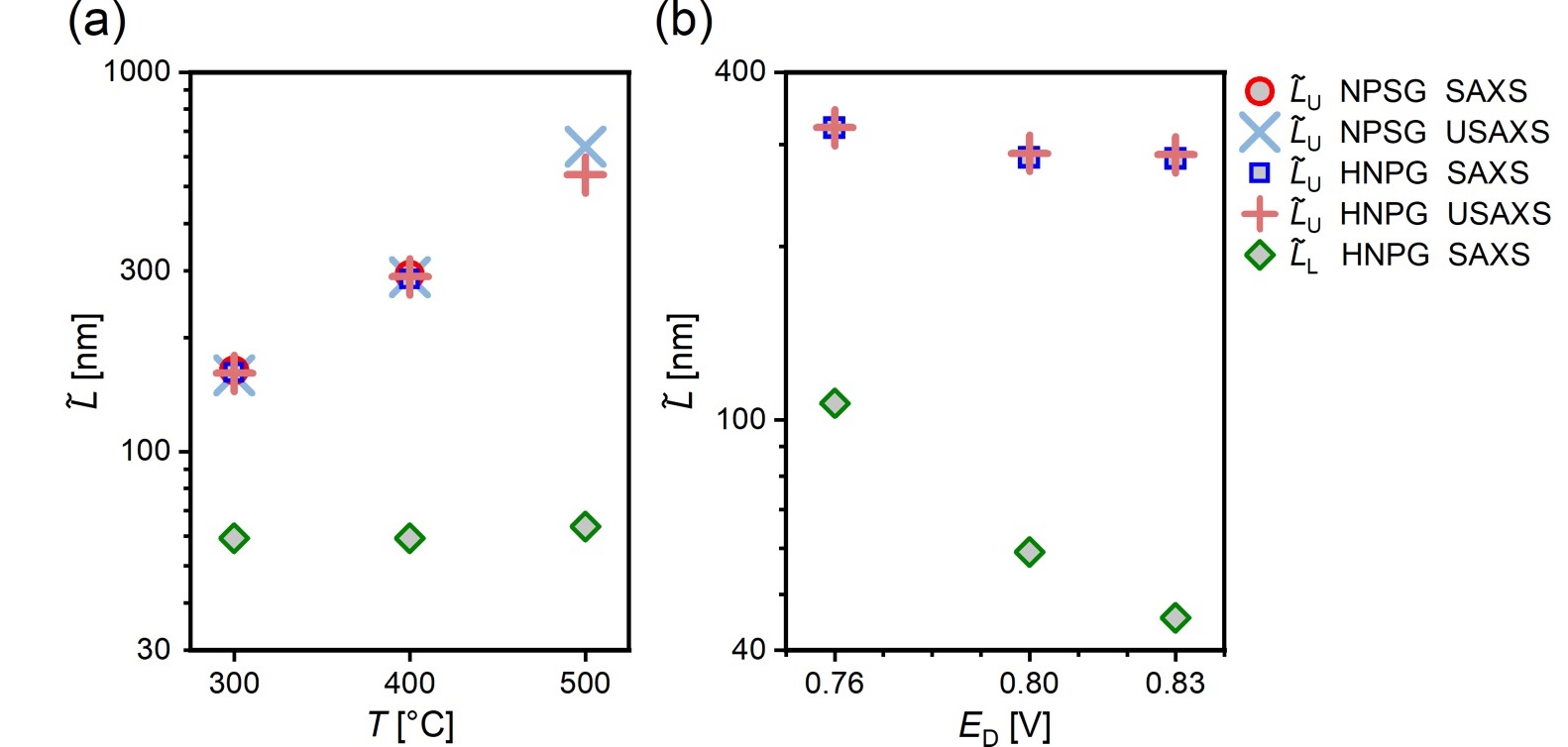

Fitting both SAXS and USAXS scattering curves with a combination of Gaussians and baseline functions allowed for quantitative analysis of the ligament spacings of both hierarchical levels. As evident from Figure 3 (a), the upper-level ligament spacing can be tuned in the range from 160 to 600 nm by increasing the annealing temperature from 300 to 500 oC. At the same time, the lower-level structure will remain unaffected exhibiting a constant ligament spacing of 61 ± 3 nm. By contrast, modifying the dealloying potential during the second dealloying step while maintaining a constant TA will have essentially no impact on the upper-level structure (nm). Increasing ED from 0.76 to 0.83 V will however induce a decrease in from 107 to 46 nm (see Figure 3 (b)).

Fig. 3 Evolution of ligament spacing, as revealed by SAXS and USAXS, of the two hierarchical levels as a function of (a) varying annealing temperature (corresponding to data presented in Figs. 2 (a,b)) and (b) dealloying potential during the second dealloying step (corresponding to data presented in Fig. 2 (c)). Credit: Phys. Rev. Mater., 2023 DOI: 10.1103/PhysRevMaterials.7.116001.

Moreover, SAXS and USAXS data allowed the evaluation of the mass-specific surface area (αm) revealing an increase when a second hierarchical level is created in HNPG samples. αm takes values between 0.6 and 4.0 m2g-1 for NPSG while for HNPG it takes values between 5.0 and 10.3 m2g-1.

Conclusions

This study demonstrates that combined small and ultra-small-angle scattering measurements provide access to key microstructural parameters, specific surface area and characteristic length scales on two hierarchical levels simultaneously, which can be used to characterize and compare the structure of nanoporous materials in general and hierarchical nanoporous gold in particular.

The analysis of the scattering data affords the quantitative evaluation of the ligament spacing as a function of varying synthesis parameters. It was thus shown that the lower hierarchical level ligament spacing can be tuned by varying the dealloying potential during the second dealloying step while keeping the upper hierarchical level intact. And vice-versa the upper hierarchical level ligament spacing can be tuned by varying the annealing temperature while keeping the lower hierarchical level unchanged.

Moreover, the study also demonstrates the complementarity between typical characterization methods for studying nanoporous metals, such as scanning electron microscopy (SEM), and SAXS/USAXS. While SEM and tomographic 3D characterizations struggle with effectively addressing two size scales simultaneously, the combination of SAXS/USAXS offers a solution by accurately determining microstructural size parameters representative for the whole volume on both hierarchical levels. The thorough analysis of both SAXS/USAXS and SEM data enabled the determination of a conversion factor between the SAXS-derived ligament spacing values and the SEM-derived ligament diameter values (L̃ ≈ (2.7 ± 0.1)LSEM ) which remarkably describes the structure on both levels of the hierarchical material. This result could facilitate comparability across studies that report either of the two distinct metrics and provides a characterization method suitable for nanoporous materials in general.

The research was originally published in the following article: [1] L. Riedel, J. Markmann, J. Weissmüller, and S. Shi, Tailoring Hierarchical Nanoporous Gold on Dual Length Scales, Phys. Rev. Mater. 7, 116001 (2023). DOI: 10.1103/PhysRevMaterials.7.116001.

[1] L. Riedel, J. Markmann, J. Weissmüller, and S. Shi, Tailoring Hierarchical Nanoporous Gold on Dual Length Scales, Phys. Rev. Mater. 7, 116001 (2023). DOI: 10.1103/PhysRevMaterials.7.116001.

[2] S. Shi, Y. Li, B.-N. Ngo-Dinh, J. Markmann and J. Weissmüller, Scaling Behavior of Stiffness and Strength of Hierarchical Network Nanomaterials , Science 371, 1026–1033 (2021). DOI: 10.1126/science.abd9391.

[3] X. Guo, J. Han, P. Liu, L. Chen, Y. Ito, et al., Hierarchical Nanoporosity Enhanced Reversible Capacity of Bicontinuous Nanoporous Metal Based Li-O2 Battery, Sci Rep 6, 1 (2016). DOI: 10.1038/srep33466.

[4] G. Wittstock, M. Bäumer, W. Dononelli, T. Klüner, L. Lührs, et al., Nanoporous Gold: From Structure Evolution to Functional Properties in Catalysis and Electrochemistry, Chem. Rev. 123, 6716 (2023). DOI: 10.1021/acs.chemrev.2c00751.