The last decades have seen an increase in climate protection awareness as well as significant advances in bio-based nanotechnology. Therefore, given the stringent sustainability requirements, wood-based nanomaterials have found applications in numerous fields such as energy, biomedicine, construction or as a replacement for petroleum-based polymers [1]. Nonetheless, the performance of these materials would greatly benefit from a more detailed understanding of the nanoscale architecture of plant cell walls [2].

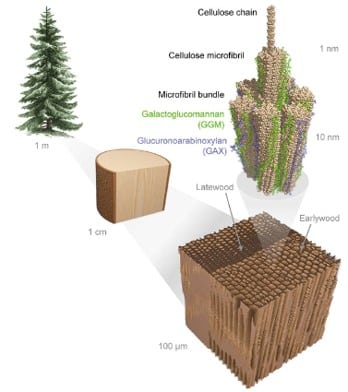

Wood is a highly hierarchical material (as depicted in Fig. 1) in which water is a key component. Its structure is composed of cellulose molecules that aggregate into semi-crystalline microfibers. The microfibers themselves bundle together with hemicelluloses and lignin forming the secondary cell walls of wood [3].

Small and wide angle X-ray scattering (SWAXS) is an efficient method to characterize hierarchical samples in general and cellulosic materials in particular, providing structural information of the different levels. On one hand, WAXS reveals characteristics of the crystal structure of cellulose microfibrils such as the lattice spacing and crystallite size. On the other hand, SAXS can be used to study larger structures such as the microfibril diameter or packing distance.

Recently, a group of researchers from the VTT Technical Research Centre of Finland and Aalto University, have employed in-situ SAXS and WAXS experiments, corroborated by molecular dynamics simulations, to study the moisture-induced structural changes in cellulose microfibril bundles of spruce wood.

Fig. 1 Graphical representation of spruce wood structure. Credit: Nano Letters 2022, DOI: 10.1021/acs.nanolett.2c00822.

Both X-ray and modeling results showed that different hierarchical levels, represented in the SAXS and WAXS data respectively, exhibit modifications in different moisture content (MC) ranges. The microfibril packing distance, observed in the SAXS data, changed mostly above MC 15% while at MC below 15% a deformation of the crystallites was evident in the WAXS data.

Deformation of cellulose crystallites observed at low moisture contents

In-situ SAXS and WAXS measurements have been used to follow the structural evolution of spruce wood during a drying process (from 95% relative humidity, RH, levels down to 10%) followed by rehydration back to RH 95%. For this purpose, a humidity-controlled sample stage was employed for accurately varying the relative humidity levels and the temperature (a detailed description of the experimental setup is presented in the Supporting Information of Ref. [3]). The actual moisture content of the samples has subsequently been determined through gravimetric measurements and it was defined as the mass ratio of water and dry sample at different RHs.

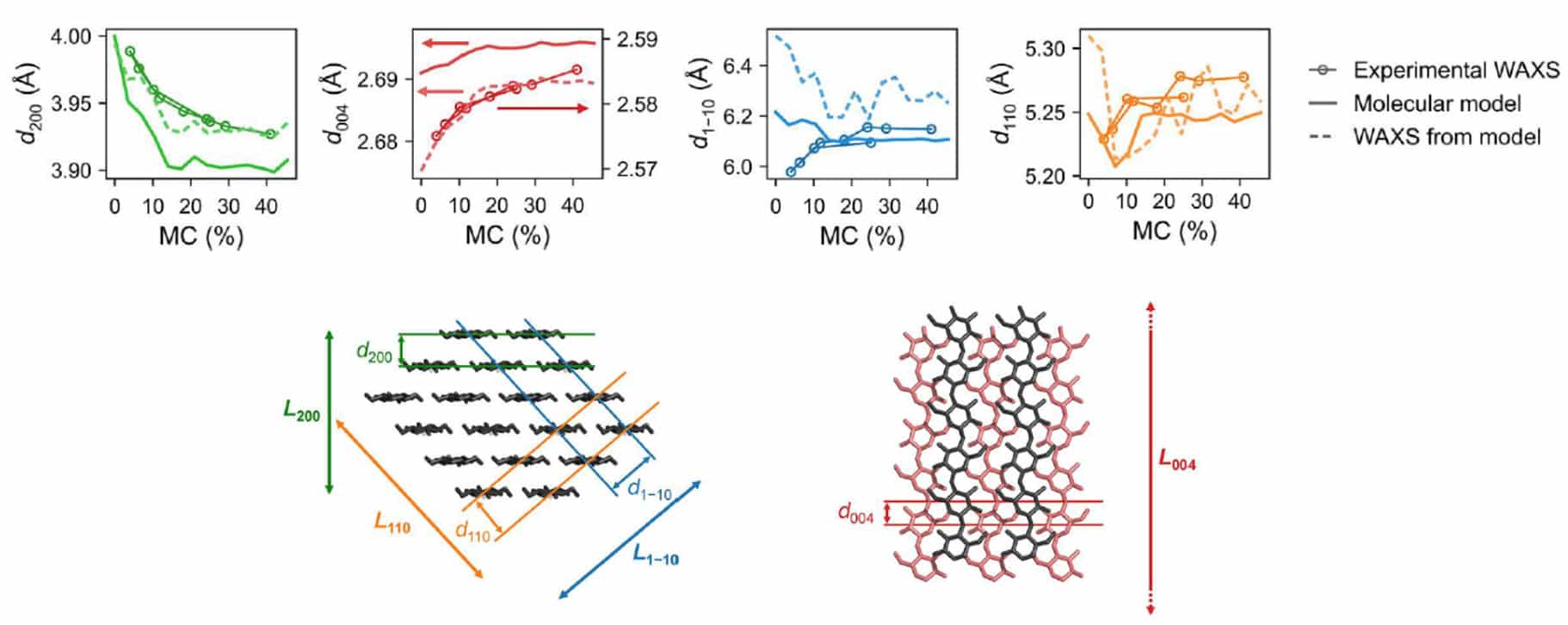

The WAXS spectrum showed clear changes in the diffraction peaks’ positions (see Fig. 2). The most prominent transitions are observed for the (200) and (004) diffraction peaks while less systematic changes take place in the diagonal directions of the microfibril cross-section (represented by the (-110) and (110) peaks). As the moisture content decreased below MC 15%, the (200) peak shifted towards higher q-values while an opposite trend was observed for the (004) peak. This indicates that the lattice spacing perpendicular to the hydrogen-bonded layers (d200) increases while the lattice spacing along the fibril axis (d004) decreases during drying. These results are in good agreement with the simulated models. In addition, the simulations showed that these variations are more prominent at the surface of the microfibril compared to the core.

Fig. 2 Variations of lattice spacings, corresponding to different directions in the crystal, extracted from WAXS data as a function of moisture content. The experimental values are shown together with simulated scattering intensities and a color-coded graphical representation of the directions in the crystal. Credit: Nano Letters 2022, DOI: 10.1021/acs.nanolett.2c00822.

Microfibril spatial reorganization observed at high moisture contents

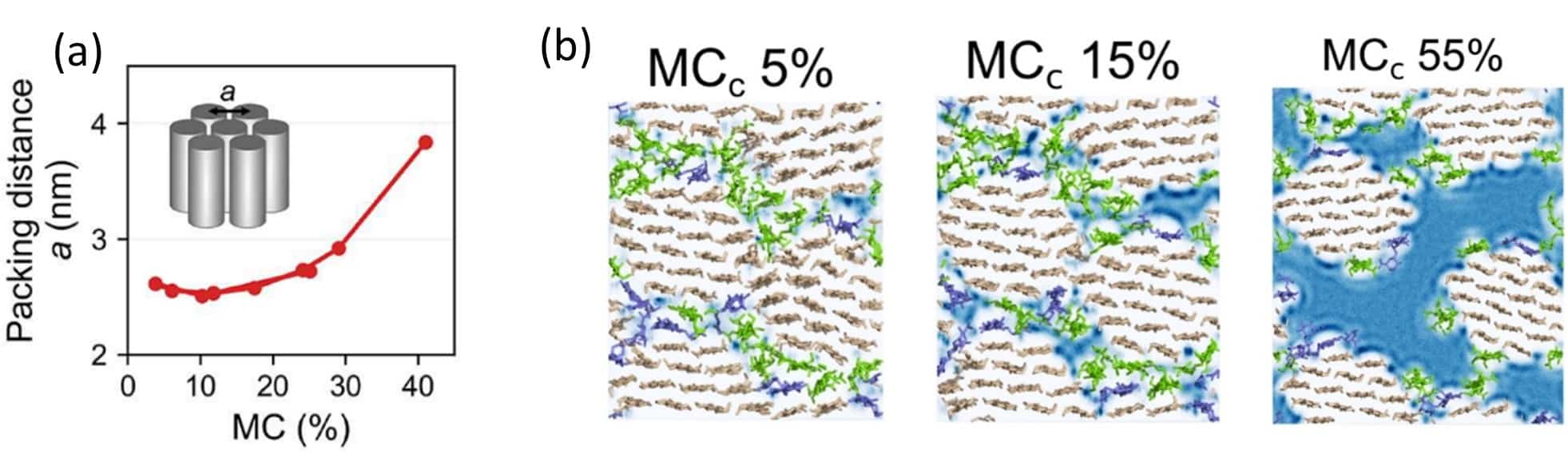

The SAXS data were fit using a model of hexagonally packed cylinders to approximate the shape and organization of microfibril, revealing important information on the microfibril packing distance. As exhibited in Fig. 3 (a), during the drying process, as water withdraws from the space between the microfibrils, a linear deswelling of the bundles is observed at MC above ~15%. The packing remained constant closer to the dry state.

This behavior is well reproduced by the molecular models (see Fig. 3 (b)) which show that the swelling of microfibril bundles, with increased MC, originates from the sorption of water to the microfibril surface and the hemicelluloses.

Fig. 3 (a) Microfibril packing distance as a function of moisture content as determined from SAXS data. (b) Simulation snapshots of the periodic bundle model of four fibrils, showcasing the moisture-induced changes. Here MCc represents the simulated moisture content and relates to MC as MC = 0.7 x MCc (where 0.7 is the approximate mass ratio of carbohydrates and total dry mass). Credit: Nano Letters 2022, DOI: 10.1021/acs.nanolett.2c00822.

Conclusions

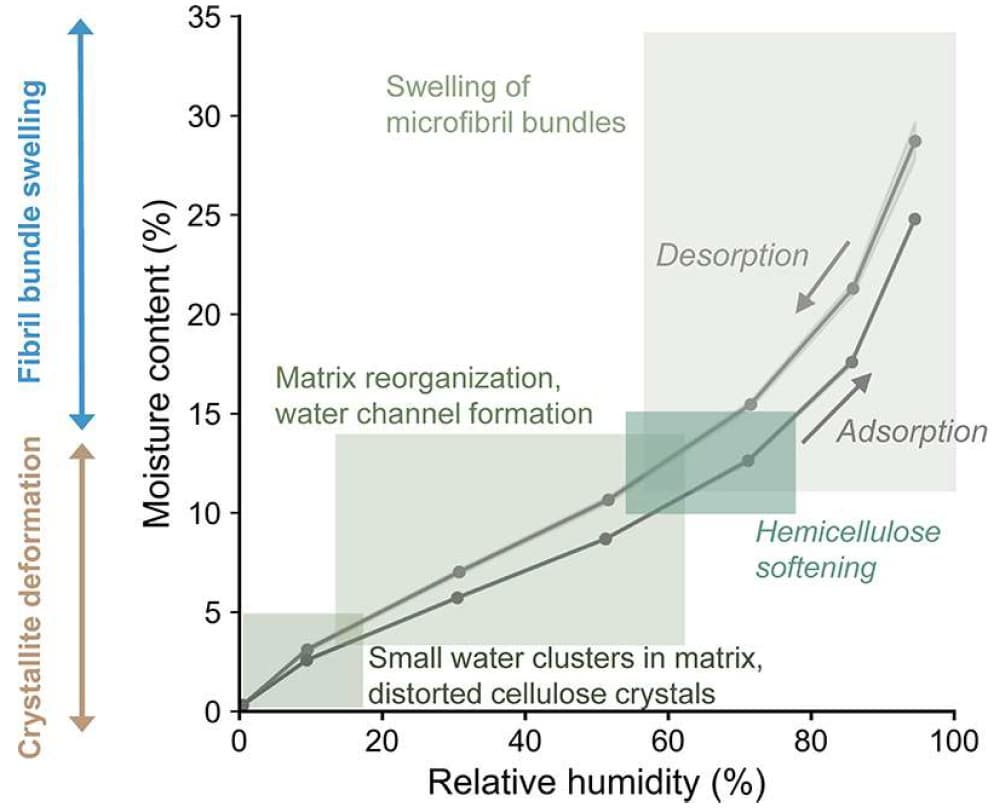

Small and wide angle X-ray scattering experiments have been used alongside molecular dynamics simulations in order to understand the nanoscale influence of moisture on the structure of spruce wood. The analysis (summarised in Fig. 4) revealed that in dry state the cellulose crystallites are deformed due to the tight packing of the immobile microfibrils. As the water content in the system increases, small water clusters are formed which help release the deforming stress on the microfibrils. Above 15% moisture content, individual water clusters merge and occupy the spaces between the microfibrils. At the same time, the swelling of the fibril bundles induces an increase in the microfibril packing distance allowing a faster water diffusion in the matrix.

Fig. 4 Summary of moisture-induced structural changes of spruce wood as determined from X-ray scattering experiments and molecular dynamics simulations. Credit: Nano Letters 2022, DOI: 10.1021/acs.nanolett.2c00822.

The research was originally published in the following article: [3] Paajanen, Antti, Aleksi Zitting, Lauri Rautkari, Jukka A. Ketoja, and Paavo A. Penttilä. “Nanoscale Mechanism of Moisture-Induced Swelling in Wood Microfibril Bundles.” Nano Letters (2022).

[1] Jiang, Feng, Tian Li, Yiju Li, Ying Zhang, Amy Gong, Jiaqi Dai, Emily Hitz, Wei Luo, and Liangbing Hu. “Wood‐based nanotechnologies toward sustainability.” Advanced Materials 30, no. 1 (2018): 1703453.

[2] Penttilä, Paavo A., Michael Altgen, Muhammad Awais, Monika Österberg, Lauri Rautkari, and Ralf Schweins. “Bundling of cellulose microfibrils in native and polyethylene glycol-containing wood cell walls revealed by small-angle neutron scattering.” Scientific reports 10, no. 1 (2020): 1-9.

[3] Paajanen, Antti, Aleksi Zitting, Lauri Rautkari, Jukka A. Ketoja, and Paavo A. Penttilä. “Nanoscale Mechanism of Moisture-Induced Swelling in Wood Microfibril Bundles.” Nano Letters (2022).