The study of metal oxides nanoparticles (NPs) is an area of intense scientific research owing to their distinct properties which make them excellent candidates for a variety of potential applications in a multitude of fields. In particular, they exhibit a high surface area to volume ratio and lower melting points compared to their bulk counterparts due to their small size, as well as high porosity and substantial van der Waals interactions. Additionally, by adjusting their composition it is possible to induce photocatalytic behavior, high toughness and wear resistance, paramagnetism, electrical conductivity or insulation properties [1].

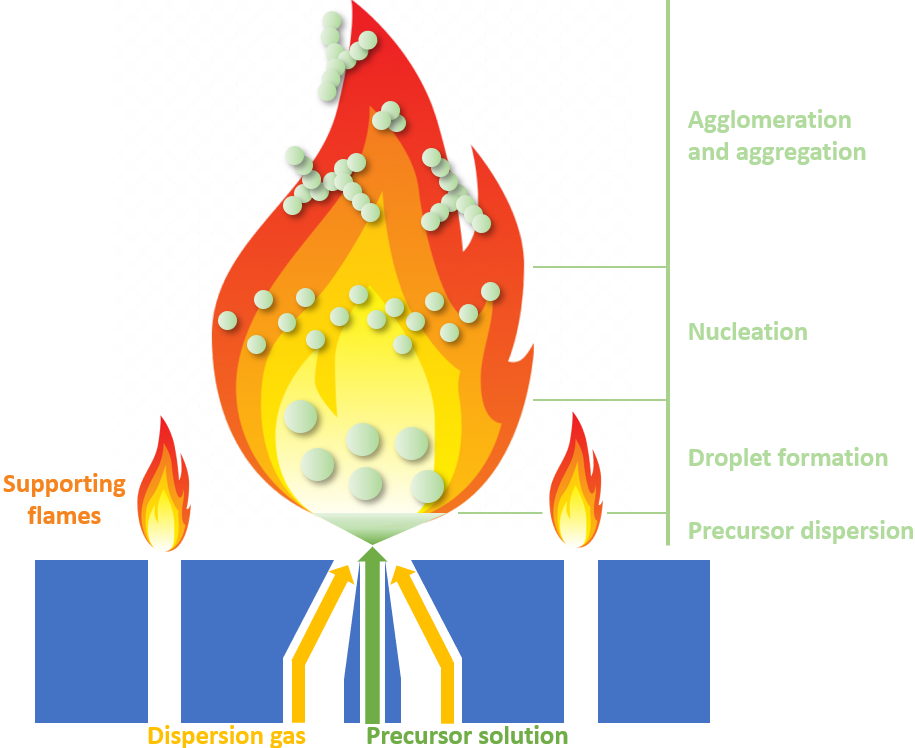

One manufacturing pathway to produce metal oxide NPs is flame spray synthesis (schematically exemplified in Fig. 1), an approach that results in the rapid formation of high purity nanoparticles concomitant with more complex structures depending on the underlying formation mechanisms. Aggregates in the form of fractal structures can be obtained by the so-called gas-to-particle route while precipitation will produce solid particles or shells of particles in the micron and submicron range. As for any manufacturing process, the aim is to produce structures consistent in shape and size in a reproducible manner. In this regard, small-angle x-ray scattering (SAXS) is an excellent structural characterization technique that can be used to probe the influence of various parameters on the final particle system. Its particularity comes from offering information on multiple structural levels, from primary particles to fractal structures, which can be a challenge for most other techniques.

Fig. 1 Schematic representation of the flame spray synthesis process

Recently, scientists from the Karlsruhe Institute of Technology have used SAXS, in conjunction with transmission electron microscopy (TEM), to study the influence of the precursor solution concentration, in the spray flame synthesis process, on the resulting primary particles and hierarchical aggregates of zirconium dioxide [1]. In contrast with TEM, where particles included in the analysis are hand-picked through a time-consuming and tedious process that presents high risks of introducing a bias in the data analysis [2] (by privileging larger particles which in general offer a higher contrast), SAXS was able to provide reliable quantitative data on the characteristics of both primary particles and fractal structures.

Characterization of primary particles and fractal structures by means of SAXS

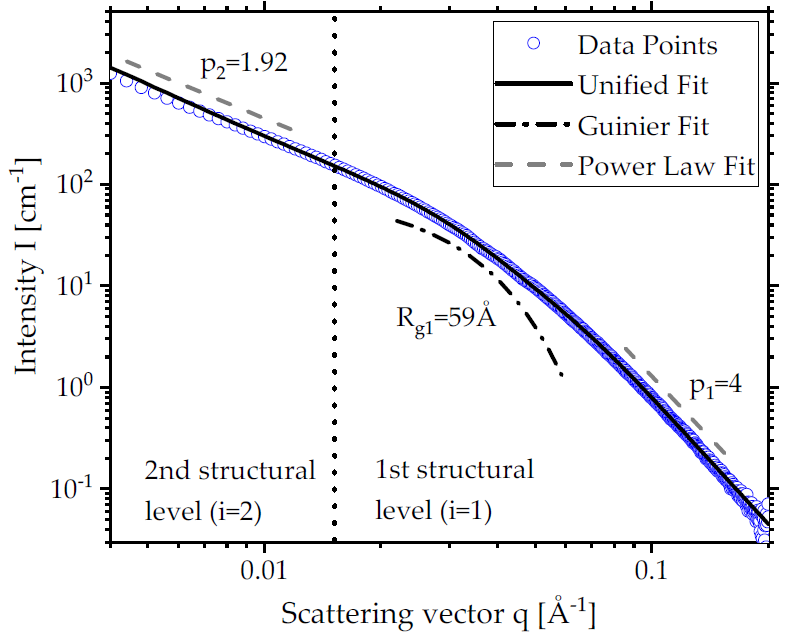

Fig. 2 SAXS scattering profile collected on a sample produced with a precursor concentration of c = 0.4 mol L-1. Dashed lines represent the local fits corresponding to each of the two structural levels defined. Credit: Materials, 2022, DOI: 10.3390/ma15062124

In a single SAXS data set, collected with an exposure time of 10 minutes, information on both primary particles and more complex larger structures (fractal structures) is obtained. As exemplified in Fig. 2 the scattering data can be divided into two regions corresponding to the two structural levels. Data collected at high q values describe the small primary particles (that form the 1st level) while from the low q values characteristics of the aggregates (that form the 2nd level) can be extracted. Local Guinier and Power Law fits will subsequently provide information about the average characteristic size of particles (through the radius of gyration Rg) and about the morphology of the underlying structure respectively. Note that for the second structural level it was not possible to perform the Guinier fit due to limitations in the q range accessible with SAXS. Ultra small angle x-ray scattering (USAXS) would have been able to provide the missing information.

Size and polydispersity of primary particles

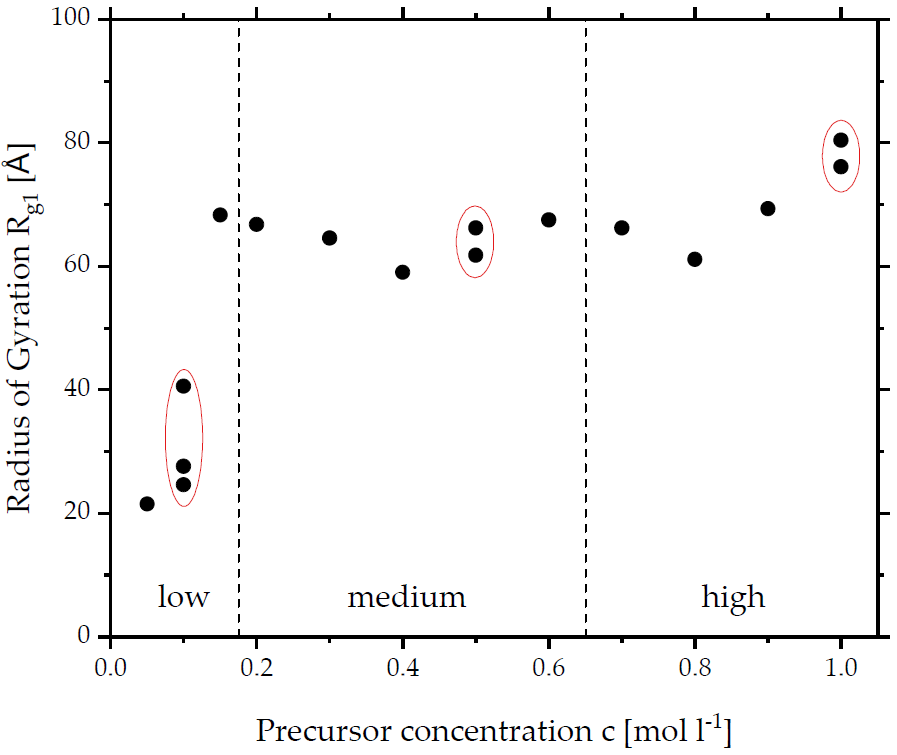

For the primary particles, the Guinier Fit revealed an average particle size of Rg1 = 59 Å at 0.4 mol L-1 concentration. At the same time, the gradual change of slope in this regime points towards a high polydispersity of the primary particles. In order to optimize the manufacturing process, the influence of the precursor concentration on the size of primary particles has been monitored. As shown in Fig. 3, the use of medium and high precursor concentrations (c > 0.2 mol L-1) yields a reproducible process with a resulting stable particle size of around 70 Å. Lower concentrations on the other hand produce unstable manufacturing conditions with variable particle radii in the range of 20 to 70 Å.

Fig. 3 The radii of gyration of primary particles produced with different precursor concentrations grouped in regions: low, medium and high. Multiple experiments are grouped with a red ellipse. Credit: Materials, 2022, DOI: 10.3390/ma15062124

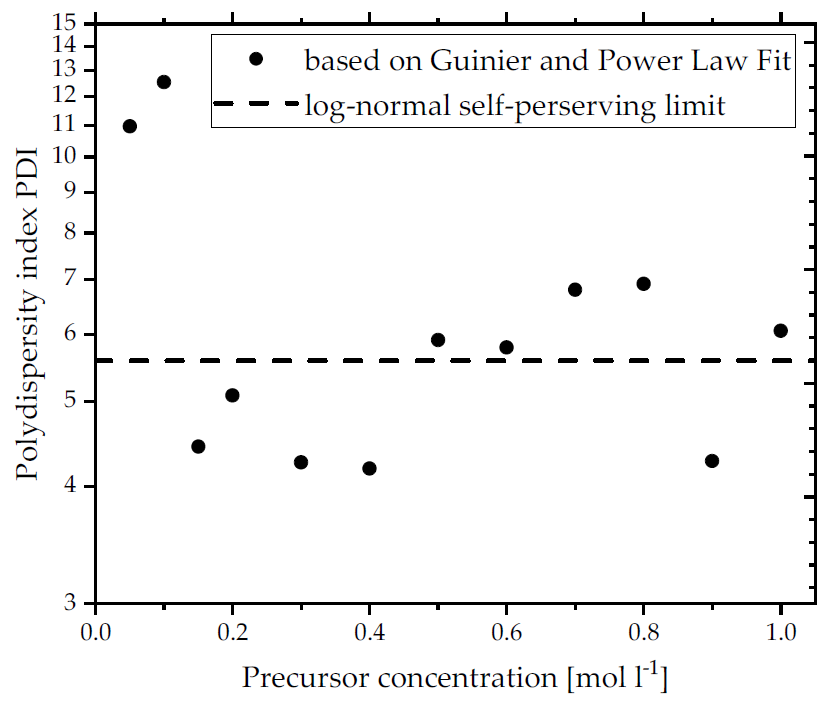

Additional parameters such as the polydispersity index (PDI) can be easily calculated using the radius of gyration. As previously mentioned, a high polydispersity is a typical characteristic of spray flame synthesis confirmed by the rather high values of the PDI (Fig. 4). However, the fact that the PDI values are scattered around the self-preserving limit for aerosol growth (PDI = 5.56) and in good agreement with results from similar experiments supports the claim of stable manufacturing conditions obtained with medium and high concentrations. At the other end, lower precursor concentrations generate PDI values as high as double the self-preserving limit proving once more the unreliability of the manufacturing process in these concentrations.

Fig. 4 Polydispersity index calculated for primary particles manufactured with different precursor concentrations. Credit: Materials, 2022, DOI: 10.3390/ma15062124

Fractal structures properties

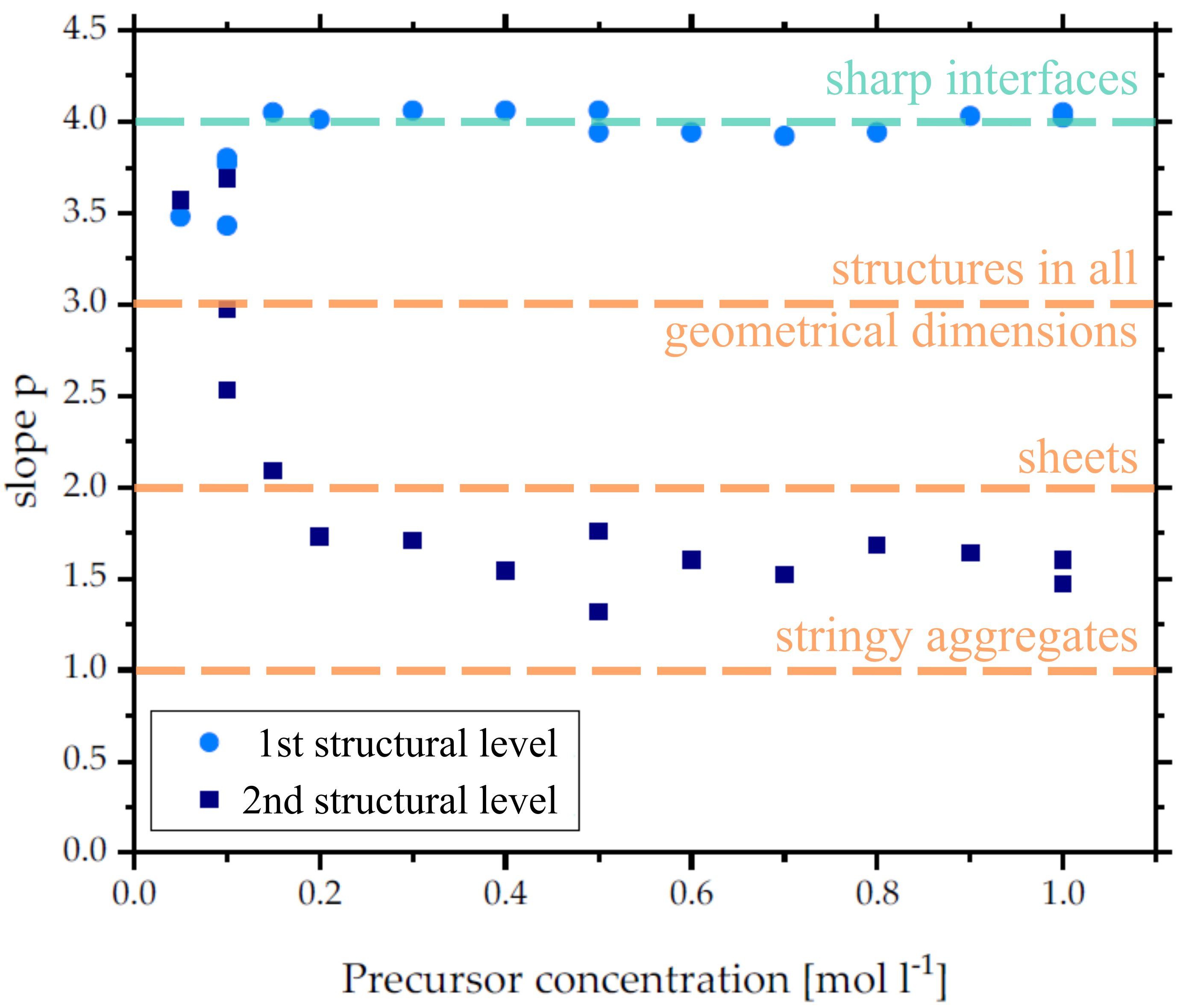

From SAXS measurements the slope p of the Power Law can be determined obtaining thus information about the fractal properties of the system. For the first structural level, it characterizes the surface of primary particles while for the second structural level it describes the shape of the fractal structures. As displayed in Fig. 5, for medium and high precursor concentrations (> 0.2 mol L-1) p takes values around 4 for primary particles pointing towards a Porod behavior with smooth surfaces and sharp interfaces. At the other end, lower concentrations generate particles with rough surfaces giving rise to smaller p values. TEM measurements were also able to confirm the aspect of smooth particles at high concentrations, however, the smaller particle sizes obtained at lower concentrations made it impossible for the technique’s resolution to resolve the roughness of the surfaces.

For the second structural level, the p values obtained at concentrations c > 0.2 mol L-1 reveal the presence of fractal structures composed of flaky aggregates with stringy parts also confirmed by TEM. At lower concentrations, the large values of p indicate a mixture of large particles and mass fractals of smaller particles both contributing to the intensity in the same scattering vector range.

Fig. 5 The slope of the power law fit corresponding to both structural levels and determined for different precursor concentrations. Credit: Materials, 2022, DOI: 10.3390/ma15062124

Conclusions

Throughout this study, the influence of precursor concentration, in the spray flame synthesis process, on the resulting primary particles and fractal structures has been investigated using SAXS and TEM measurements. SAXS proves to be an excellent tool for studying such complex mixtures of single particles and aggregates. A single data set contains information on particle size, polydispersity and fractal properties. Additionally, particle size distribution analysis is also presented in the original work. Furthermore, wide angle X-ray scattering has been used to demonstrate the formation of the desired chemical compound, namely zirconium dioxide.

The research revealed that low precursor concentrations (< 0.2 mol L-1) lead to unstable and inconsistent manufacturing conditions. Stable and reproducible processing conditions are however obtained with medium (c = 0.2-0.6 mol L-1) and high (c = 0.7-1.0 mol L-1) precursor concentrations. Finally, the researchers were able to identify the particle formation mechanism, namely the gas-to-particle route as no evidence was found for the formation of particles larger than half a micron.

The research was originally published in the following article: [1] Simmler, Mira, Manuel Meier, and Hermann Nirschl. “Characterization of Fractal Structures by Spray Flame Synthesis Using X-ray Scattering.” Materials 15, no. 6 (2022): 2124.

[1] Simmler, Mira, Manuel Meier, and Hermann Nirschl. “Characterization of Fractal Structures by Spray Flame Synthesis Using X-ray Scattering.” Materials 15, no. 6 (2022): 2124.

[2] Kammler, Hendrik K., Gregory Beaucage, Roger Mueller, and Sotiris E. Pratsinis. “Structure of flame-made silica nanoparticles by ultra-small-angle X-ray scattering.” Langmuir 20, no. 5 (2004): 1915-1921.