– Application highlight –

Nanocomposites are a class of high-performance materials which are attracting attention in various industries such as for example the automotive industry. They include a spectrum of low-cost yet high-performance materials capable of exhibiting mechanical, thermal and processing properties which are valuable for automotive manufacturing. Their bulk properties are determined by their structure on the nanoscale, therefore, the accurate analysis of small-scale structure is essential to the characterization and development of nanocomposites. X-ray scattering technology can provide unprecedented insight into the many parameters that affect nanocomposite properties.

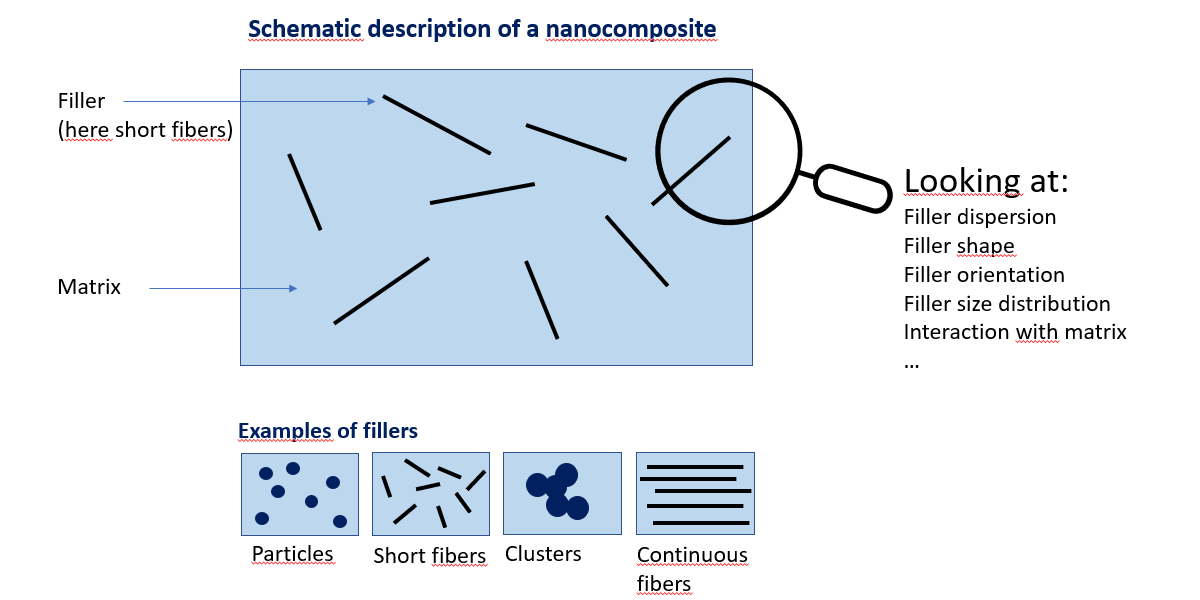

Nanocomposites are a type of composite material in which nanoscale particles or fibres (the filler) consisting of one or more materials are dispersed throughout a bulk (matrix) material. Both the filler(s) and the matrix retain elements of their own bulk material properties, while the nanoscale parameters of the fillers contribute novel properties to the nanocomposite. These parameters include dispersion, shape, orientation and size distribution of the filler particles, as well as their interaction with the bulk matrix.1-4

As a result, nanocomposites are a very broad class of materials whose properties can be finely tuned during production by altering the physical and chemical properties of the constituent materials.

Analysis of such materials via microscope yields useful information about the individual geometries of nanoparticles in composite materials; however, it fails to deliver statistical information about nanoparticle size distribution and volume fraction. As such, microscopy techniques are unable to provide a meaningful characterization of variations throughout a larger sample volume. In addition, many nanocomposite materials are opaque to visible light or require complex sample preparation, which drastically limits the efficacy of microscope analysis.

Small-Angle X-ray Scattering for Nanocomposites Characterization

Small-Angle X-ray Scattering (SAXS) offers a solution to the statistical analysis of nanoparticles in nanocomposite materials. SAXS uses X-ray scattering to determine nanoscale parameters within a statistically significant volume (usually around 1mm3), such as the size distribution of nanoparticles in nanocomposites.8

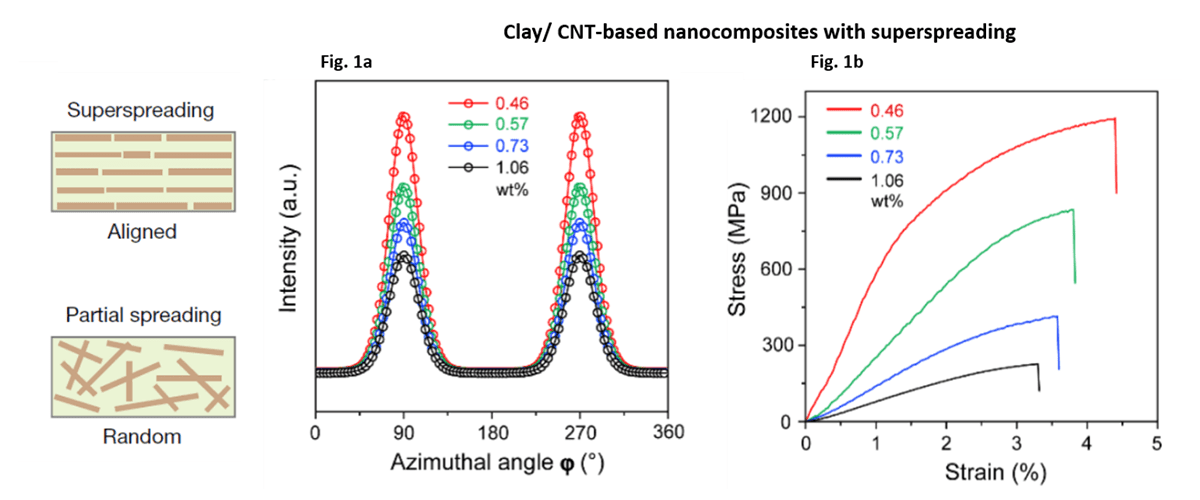

Figure 1 below illustrates an example of measurements with SAXS in the case of nanocomposites with highly ordered layered structures produced with a new manufacturing strategy6.

Figure 1 – X-ray scattering measurements and mechanical properties of Clay/CNT-based nanocomposite films produced by a new method of shear-flow-induced alignment of nanosheets (superspreading). Fig 1a: 1D plots of X-ray scattering intensity depending on azimuth angle for different concentrations of nanofillers (in wt%, see key)-orientation ordered parameter and nanosheets interlayer distance can be calculated (not shown). Fig 1b: corresponding stress-strain curves for the different nanocomposites. Adapted from Zhao, C., Zhang, P., Zhou, J. et al. Layered nanocomposites by shear-flow-induced alignment of nanosheets (Supplementary Data). Nature 580, 210–215 (2020).

Application in the automotive industry

Demand for fuel economy and low-emissions in the automotive industry have increased demand for lightweight structural materials in vehicles, and nanocomposites offer appealing solutions.5 Offering comparable or superior reliability to metals, switching to nanocomposite materials can offer significant weight reductions without compromising on structural integrity.

In addition, the unique properties of nanocomposites can bring many desirable properties to non-structural components; including increased durability, noise dampening and corrosion resistance.5 Additional functional properties such as UV-shielding can also be achieved through the use of nanocomposites.7

Car tires are a widespread example of an application of nanocomposites in the automotive industry. The extreme durability required of tires can be achieved and enhanced through the use of nanocomposite fillers, often silica nanoparticles or carbon black, which have been shown to offer higher strength and deformation resistance than unfilled rubber polymers. Analysis of silica clusters in rubber has enabled the development of new materials for the manufacture of tires.

X-ray Scattering for Multiscale Filler Structure Characterization

A complete and meaningful understanding of the properties of a nanocomposite material requires analysis at a range of length scales: from the surface structure of a nanoparticle, to its overall geometry, and from nanoparticle clusters to agglomerates of various scales.

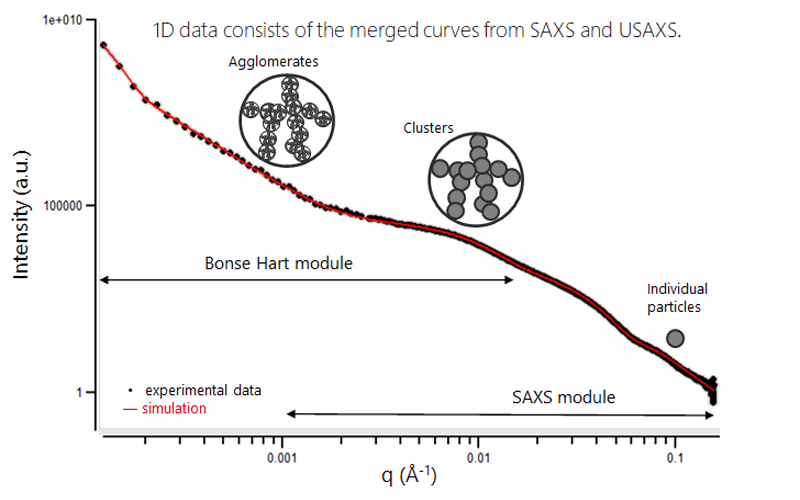

A standard SAXS setup allows measurement of the radius of gyration (an indicator of size) of the individual particles and aggregates of particles. With a Bonse-Hart Ultra-Small- Angle X-ray Scattering (USAXS) setup one can access larger length scales and obtain information about agglomerates, as shown in the curve below.

Figure 2 – Combined SAXS and USAXS experimental curve of silica clusters in rubber (sequential automatic measurement performed on a Xeuss) and multiscale fit model. Graphic inserts show different type of particles analyzed

In this case, simulation of the curve yielded information about individual particle size as well as cluster and agglomerate sizes together with fractal dimensions at 3 length scales.

Using SAXS to obtain a size distribution of filler particles in nanocomposites, in conjunction with microscopy techniques to characterize individual particles, can give a comprehensive and information-rich description of nanocomposite structure.

Analysis of results using standard models is fast, and especially useful for comparing different formulation parameters of samples. Additionally, quantitative models of the complex filler structure of industrial nanocomposites have been developed. For example, use of high-performance microscopy techniques such as Tunneling Electron Microscopy (TEM) in conjunction with SAXS can yield a full characterization of inter-aggregate interactions, aggregate polydispersity and compacity in addition to full hierarchical structure.9

The Xenocs Xeuss is a high-performance SAXS beamline for laboratory use, designed to facilitate Ultra-Small-, Small- and Wide-Angle X-ray Scattering (USAXS, SAXS & WAXS) for soft matter and nanomaterial analysis. It offers quick characterization of filler networks in nanocomposites such as bio-rubber,10 carbon black filler for rubber,11 or graphene oxide with Poly(ethylene methyl acrylate).12

The Xeuss is configurable for a huge range of length scales, capable of providing particle size distributions from a few nanometers to 350 nm, and an additional Bonse-Hart USAXS add-on enables the characterization of large structures over 4 μm. Despite providing cutting-edge analysis, the Xeuss is designed with ease-of-use in mind: it is configurable for fully remote operation and its large vacuum chamber with stationary sample during measurement ensures maximum versatility. 13

Discover other Xenocs SAXS instruments on Xenocs product page, and especially the Nano inxider8 for SAXS, WAXS and GISAXS studies on all types of samples.

References and Further Reading

- Genix, A.-C., Bocharova, V., Carroll, B., Lehmann, M., Saito, T., Krueger, S., He, L., Dieudonné George, P., Sokolov, A.P., Oberdisse, J.. Understanding the Static Interfacial Polymer Layer by Exploring the Dispersion States of Nanocomposites. ACS Appl. Mater. Interfaces 11, 17863–17872 (2019).

- Zhang, P. & Kraus, T. Anisotropic nanoparticles as templates for the crystalline structure of an injection-molded isotactic polypropylene/TiO 2 nanocomposite. Polymer. 130, 161–169 (2017).

- Pletsch, H., Tebbe, M., Dulle, M., Förster, B., Fery, A., Förster, S., Greiner, A. & Agarwal, S., Reversible gold nanorod alignment in mechano-responsive elastomers. Polymer. 66, 167–172 (2015).

- Heinrich, G., Klüppel, M. & Vilgis, T. A. Reinforcement of elastomers. Opin. Solid State Mater. Sci. 6, 195–203 (2002).

- Garcés, M., Moll, D. J., Bicerano, J., Fibiger, R. & Mcleod, D. G. Polymeric Nanocomposites for Automotive Applications. Adv. Mat., 12, 1835-1839 (2000).

- Zhao, C., Zhang, P., Zhou, J., Qi, S., Yamauchi, Y., Shi, R., Fang, R., Ishida, Y., Wang, S., Tomsia, A.P., Jiang, L., Liu, M., Layered nanocomposites by shear-flow-induced alignment of nanosheets. Nature, 580, 210–215 (2020).

- Olson, E., Li, Y., Lin, F.-Y., Miller, A., Liu, F., Tsyrenova, A., Palm, D., Curtzwiler, G.W., Vorst, K.L., Cochran, E. & Jiang, S., Thin Biobased Transparent UV-Blocking Coating Enabled by Nanoparticle Self-Assembly. ACS Mater. Interfaces 11, 24552–24559 (2019).

- Size distribution of nanoparticles: powders, dispersions and composites. Available at: https://www.xenocs.com/size-distribution-of-nanoparticles-powders-dispersions-and-composites/

- Oberdisse, J., Pyckhout-Hintzen, W., Straube, E., Structure Determination of Polymer Nanocomposites by Small Angle Scattering, Recent Advances in Polymer Nanocomposites, Chapter 12 (2019).

- Manoharan, P. & Naskar, K. Biologically sustainable rubber resin and rubber-filler promoter: a precursor study. Adv. Technol. 28, 1642–1653 (2017).

- Mondal, T., Bhowmick, A.K., Ghosal, R., Mukhopadhyay, R., Expanded Graphite as an Agent Towards Controlling the Dispersion of Carbon Black in Poly (Styrene –co-Butadiene) Matrix: An Effective Strategy Towards the Development of High Performance Multifunctional Composite, Polymer, 146, 31-41 (2018).

- Ganguly, S., Mondal, S., Das, P., Bhawal, P., Das, T.K., Ghash, S., Remanan, S. & Das, N.C., An Insight Into the Physico-Mechanical Signatures of Silylated Graphene Oxide in Poly(ethylene methyl acrylate) Copolymeric Thermoplastic Matrix. Macromol. Res. 27, 268–281 (2019).

- USAXS SAXS WAXS Nanostructure – Lab Beamline Characterization. Available at: https://xenocs.com/products/xeuss-3-0/.

Products

Discover our related products